Correct use of slotting knife in ink printing machine

Carton printing slotting machine, forming machine and various printing die-cutting slotting and other multi-functional combined machines. With the characteristics of high-quality higher education and compact structure, they are widely used by carton packaging enterprises. Slotting cutter is one of the necessary tools. Its service life directly affects the slotting quality and manufacturing cost of cartons. It is one of the difficult problems that need to be improved in the quality management and cost management of similar enterprises. The tool wear is related to the cut paper. When the slotting cutter works, the ruler mouth produces cutting movement on the paperboard and the surface is subject to relative friction. The sand content in many paperboards is as high as 5% ~ l0%, and the sand particles have a strong grinding and scraping effect relative to the edge, which makes the metal on the edge surface gradually plastic deformation and fatigue wear off. The service life of the cutter decreases with the increase of service time and the increase of sand content (quartz sand, etc.) and impurities of the cut paperboard.

Some problems of carton printing slotting machine are similar: first, the slotting knife (upper knife) can only be used once and has a short service life; Second, the effect of grinding and reuse is poor, and the slotting quality is unstable; Third, the wear resistance of the cutting edge is poor, and some cutting edges crack locally; Fourth, new knives are frequently added, with large expenditure and high production cost. Methods to improve service life this paper refers to some factors that are objectively difficult to avoid or the service life of cutting tools is affected by accidental bumps, which will not be discussed here. After subjective efforts, the practical way is to solve the problems of reuse of old knives and selection of new knives, so as to prolong the service life of slotting knives.

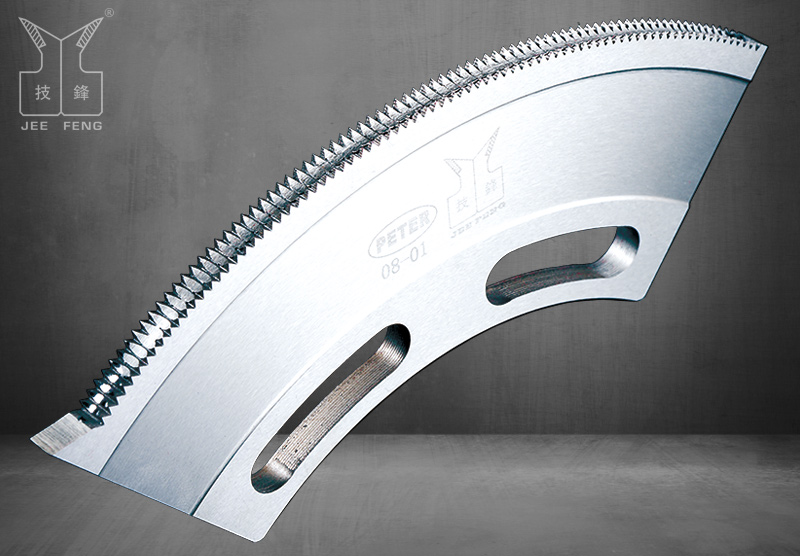

In today's fierce market competition with quality and price as the core, this problem is more and more concerned by relevant enterprise leaders, which promotes enterprises to tap potential, innovate, save expenditure and increase efficiency, and take the road of connotative development. This paper discusses how to improve the service life of slotting cutter. Slotting knife includes upper knife and lower knife. Common upper knife includes arc knife and arc sawtooth knife; The lower knife has semicircular acute angle knife or semicircular right angle knife and semicircular groove wide retaining ring. The service life of slotting knife depends on whether the slotting quality of paperboard meets the product standard. Generally, the slotting quality decreases gradually with the wear of the cutting edge of the tool, resulting in burr, burr, fragmentation and waste. When the product does not meet the standard, the slotting tool needs to be replaced.